Initiatives

for quality

With "Customer First" and "Quality First" as management guidelines,

we provide high-quality products and services to satisfy our customers.

Quality Policy

As a core supplier within Daihatsu Group, we devote ourselves to "Quality First" in all aspects of our work and nurture a strong trust-based relationship with our customers.

- 1.We will completely focus on the idea that "Own Process Completion" and "The next process is our customer" in all aspects of our activities.

- 2.We will pursue manufacturing technologies and offer products and technologies within the high-tensile strength steel press and metal sheet fields.

- 3.We will increase our sensitivity towards all abnormalities and respond thoroughly and appropriately to all "non-normal" conditions.

- 4.By maintaining a steady attitude as we challenge ourselves in pursuing "Quality First," we aim to develop workers and workplaces that strongly value quality.

Quality management from the development phase to the production phase

Development, Production Department

We take part in SE (simultaneous engineering) from the development phase in order to respond to our customers' needs at an early stage. We are actively involved in solving issues and reducing costs during the development phase to eliminate noncompliance in mass production, establish an efficient mass production system, and reduce preparation time for manufacturing.

Production Department

Following "The next process is our customer" as our motto, we thoroughly assess and improve the quality of each process.

We ensure only good products will be passed on to the next step by having well-trained and experienced workers who have studied from a manual with all the key points of quality control assess and improve the quality, implementing automated inspection machines, and putting "poka-yoke," or "mistake-proofing," mechanisms in place.

Quality Control Testing for Mass-Produced Products

We actively carry out product precision inspections, verification tests (for damage, degradation, or cuts) on product features (such as surface coating treatment, heat treatment, welding), and also conduct verification tests on how much the customers trust us in meeting their expectations to ensure quality during mass production. We conduct these tests based on the quality control plan and are taking steps to maintain quality during mass production.

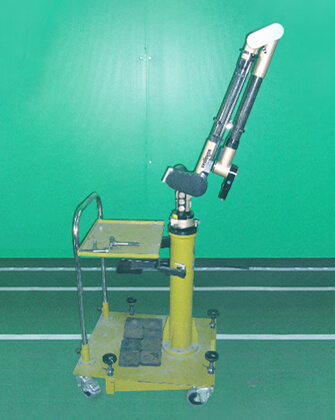

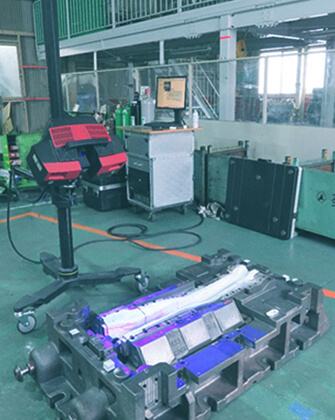

for Propeller Shafts

Measuring Devices

for Propeller Shafts